Plastic Additives

Material Safety Data Sheet - PUREfos 168

Technical Data Sheet - PUREfos 168

1. COMPANY DETAILS

CONTACT INFORMATION:

Polygel Organometallic (Brunei) Sdn. Bud.

Unit 6 & 7, Block L,

Bangunan Pengkalan Gadong,

Jalan Tungku, Gadong BE3519,

Brunei Darussalam

TEL: ++91- 260 3983500

FAX: ++91- 260 3983508

2. PRODUCT INFORMATION:

PRODUCT NAME: PUREfos 168

CHEMICAL NAME: TRIS (2, 4 DI TERT BUTYLPHENYL) PHOSPHITE

SYNONYMS: N/A

HAZARDOUS INGREDIENTS

There are no additional ingredients present which, within the current knowledge of the supplier and in the concentrations applicable, are classified as hazardous to health or the environment and hence require reporting in this section.

3. HAZARDOUS IDENTIFICATION

Potential Health Effects: No any special hazards.

Primary route of entry: Ingestion, Skin, Inhalation, Eyes

Aquatic toxicity: May be harmful to aquatic plant or animal if a large quantity released.

4. FIRST AID MEASURES

Eye contact: splash clean water in to the eyes for more than 15 minutes and if irritation continues seek medical attention

Skin contact: wash with soap water and if irritation continues seek medical attention

Inhalation: move the person to open space for air and give artificial respiration if required and obtain medical attention

Ingestion: Do not induce vomiting. Never give anything by mouth to an unconscious person. Contact physician immediately.

5. FIRE FIGHTING MEASURES

Extinguishing media: Foam, Dry chemical, CO2.

Safety measures: use proper safety equipment (breathing apparatus, full protective clothing in fire conditions)

Unusual explosion: packed container can build up pressure when exposed to high heat. Keep fire exposed containers cool by spraying with water.

Hazardous decomposition products: Carbon monoxide, Carbon dioxide, Oxides of Nitrogen, Toxic vapors.

6. ACCIDENTAL RELEASE MEASURES

NOTE: Review FIRE FIGHTING MEASURES and HANDLING (PERSONNEL) sections before proceeding with clean-up.

Use appropriate PERSONAL PROTECTIVE EQUIPMENT during clean-up.

Initial Containment

Remove source of heat, sparks, flame, impact, friction or electricity. Prevent material from entering sewers, waterways, or low areas.

Spill Clean Up

Soak up with sawdust, sand, oil dry or other absorbent material.

Accidental Release Measures

Place in container for disposal. Sweep up or use non- sparking shovel for cleanup. Flush residue with water and remove flush to an approved permitted treatment system

7. TOXICOLOGICAL INFORMATION

Acute Oral toxicity: LD 50 (rat) ;> 2000 g/kg

Acute dermal toxicity; LD 50 (rat) ;> 2000 g/kg

Acute inhalation toxicity; No death or substance related symptoms were recorded.

Primary skin irritation: Not an irritating (Rabbits)

Eye irritation: Not an irritating (Rabbits)

8. PHYSICAL & CHEMICAL PROPERTIES

1) Color : White to off white

2) Form : Powder

3) PH : 6.0

4) Odor : Odorless

5) Melting point : 183 – 186 Deg C

6) Flash Point : >150 Deg C

7) Specific Gravity : 1.03 @ 20 Deg C

8) Viscosity cps : No data Available

9) Water solubility : Insoluble

9. HANDLING AND STORAGE

Do not breathe vapor and avoid contact with skin, eye etc.

All electrical equipments must be adequately flame proof.

Store in a cool and dry place, which is well ventilated and keep the container tightly sealed. When handlings, do not eat, drink or smoke.

Storage life: 1 year in original unopened container.

Avoid ingress of moisture by keeping containers properly sealed when not in use.

Keep away from sources of ignition – no smoking.

10. EXPOSURE CONTROLS AND PERSONAL PROTECTION

Engineering Controls

Use only with adequate ventilation. Keep container tightly closed. Vent dryer or exhaust fumes outside work area.

Personal Protective Equipment

EYE/FACE PROTECTION

Wear safety glasses or coverall chemical splash goggles.

RESPIRATORS

Where there is potential for airborne exposures in excess of applicable limits, wear NIOSH approved respiratory protection.

PROTECTIVE CLOTHING

Where there is potential for skin contact have available and wear as appropriate, impervious gloves, apron, pants, and jacket.

11. STABILITY AND REACTIVITY DATE

Stability- Stable.

Condition to avoid: Avoid electro-static discharge, Avoid source of ignition.

Substance to avoid: Strong oxidizing agent, strong acids, strong alkalis.

Decomposition products: No decomposition expected under normal storage conditions.

Possible Hazards reaction: No hazards reaction known.

12. SPILL OR LEAK

Use appropriate personal protective equipment before cleanup. Soak up with an inert adsorbent material. Do not apply water to large spills. Sweep up or use a non – sparking shovel for cleanup.

13. DISPOSAL CONSIDERATIONS

Waste Disposal Treatment, storage, transportation, and disposal must be in accordance with applicable Federal, State/Provincial, and Local regulations.

14.TRANSPORTATION

DOT

Proper Shipping Name : Not Regulated.

Hazard Class : Not Regulated

I.D. No. (UN/NA) : Not Regulated

DOT Label(s) : Not Regulated

Proper Shipping Name : Not Regulated

Hazard Class : Not Regulated

UN No. : Not Regulated

DOT/IMO Label : Not Regulated

Special Information : FLASH POINT: > 150 Deg C

Packing Group : Not Regulated

15.REGULATORY INFORMATION

SARA 311/312 Chronic health hazard: Not known

SARA 322/312 Acute health hazards: No

SARA311/312 Fire hazard: No

SARA311/312 Sudden Pressure: No

SARA311/312 Reactivity Hazard: No

CERCLA Hazardous substance: None

Section 313 toxic chemicals: None

TSCA inventory status: yes

16.OTHER INFORMATION

NFPA Hazard codes:

Health: 1 Fire: 1 Reactivity: 0

HMIS III rating

Health: 1 Flammability: 1 Physical Hazard: 0

CONTACT INFORMATION:

Polygel Organometallic (Brunei) Sdn. Bud.

Unit 6 & 7, Block L,

Bangunan Pengkalan Gadong,

Jalan Tungku, Gadong BE3519,

Brunei Darussalam

TEL: ++91- 260 3983500

FAX: ++91- 260 3983508

2. PRODUCT INFORMATION:

PRODUCT NAME: PUREfos 168

CHEMICAL NAME: TRIS (2, 4 DI TERT BUTYLPHENYL) PHOSPHITE

SYNONYMS: N/A

HAZARDOUS INGREDIENTS

| COMPONENT | % | CAS NO |

|---|---|---|

| TRIS (2, 4 DI TERT BUTYLPHENYL) PHOSPHITE | >98 | 31570-04-4 |

There are no additional ingredients present which, within the current knowledge of the supplier and in the concentrations applicable, are classified as hazardous to health or the environment and hence require reporting in this section.

3. HAZARDOUS IDENTIFICATION

Potential Health Effects: No any special hazards.

Primary route of entry: Ingestion, Skin, Inhalation, Eyes

Aquatic toxicity: May be harmful to aquatic plant or animal if a large quantity released.

4. FIRST AID MEASURES

Eye contact: splash clean water in to the eyes for more than 15 minutes and if irritation continues seek medical attention

Skin contact: wash with soap water and if irritation continues seek medical attention

Inhalation: move the person to open space for air and give artificial respiration if required and obtain medical attention

Ingestion: Do not induce vomiting. Never give anything by mouth to an unconscious person. Contact physician immediately.

5. FIRE FIGHTING MEASURES

Extinguishing media: Foam, Dry chemical, CO2.

Safety measures: use proper safety equipment (breathing apparatus, full protective clothing in fire conditions)

Unusual explosion: packed container can build up pressure when exposed to high heat. Keep fire exposed containers cool by spraying with water.

Hazardous decomposition products: Carbon monoxide, Carbon dioxide, Oxides of Nitrogen, Toxic vapors.

6. ACCIDENTAL RELEASE MEASURES

NOTE: Review FIRE FIGHTING MEASURES and HANDLING (PERSONNEL) sections before proceeding with clean-up.

Use appropriate PERSONAL PROTECTIVE EQUIPMENT during clean-up.

Initial Containment

Remove source of heat, sparks, flame, impact, friction or electricity. Prevent material from entering sewers, waterways, or low areas.

Spill Clean Up

Soak up with sawdust, sand, oil dry or other absorbent material.

Accidental Release Measures

Place in container for disposal. Sweep up or use non- sparking shovel for cleanup. Flush residue with water and remove flush to an approved permitted treatment system

7. TOXICOLOGICAL INFORMATION

Acute Oral toxicity: LD 50 (rat) ;> 2000 g/kg

Acute dermal toxicity; LD 50 (rat) ;> 2000 g/kg

Acute inhalation toxicity; No death or substance related symptoms were recorded.

Primary skin irritation: Not an irritating (Rabbits)

Eye irritation: Not an irritating (Rabbits)

8. PHYSICAL & CHEMICAL PROPERTIES

1) Color : White to off white

2) Form : Powder

3) PH : 6.0

4) Odor : Odorless

5) Melting point : 183 – 186 Deg C

6) Flash Point : >150 Deg C

7) Specific Gravity : 1.03 @ 20 Deg C

8) Viscosity cps : No data Available

9) Water solubility : Insoluble

9. HANDLING AND STORAGE

Do not breathe vapor and avoid contact with skin, eye etc.

All electrical equipments must be adequately flame proof.

Store in a cool and dry place, which is well ventilated and keep the container tightly sealed. When handlings, do not eat, drink or smoke.

Storage life: 1 year in original unopened container.

Avoid ingress of moisture by keeping containers properly sealed when not in use.

Keep away from sources of ignition – no smoking.

10. EXPOSURE CONTROLS AND PERSONAL PROTECTION

Engineering Controls

Use only with adequate ventilation. Keep container tightly closed. Vent dryer or exhaust fumes outside work area.

Personal Protective Equipment

EYE/FACE PROTECTION

Wear safety glasses or coverall chemical splash goggles.

RESPIRATORS

Where there is potential for airborne exposures in excess of applicable limits, wear NIOSH approved respiratory protection.

PROTECTIVE CLOTHING

Where there is potential for skin contact have available and wear as appropriate, impervious gloves, apron, pants, and jacket.

11. STABILITY AND REACTIVITY DATE

Stability- Stable.

Condition to avoid: Avoid electro-static discharge, Avoid source of ignition.

Substance to avoid: Strong oxidizing agent, strong acids, strong alkalis.

Decomposition products: No decomposition expected under normal storage conditions.

Possible Hazards reaction: No hazards reaction known.

12. SPILL OR LEAK

Use appropriate personal protective equipment before cleanup. Soak up with an inert adsorbent material. Do not apply water to large spills. Sweep up or use a non – sparking shovel for cleanup.

13. DISPOSAL CONSIDERATIONS

Waste Disposal Treatment, storage, transportation, and disposal must be in accordance with applicable Federal, State/Provincial, and Local regulations.

14.TRANSPORTATION

DOT

Proper Shipping Name : Not Regulated.

Hazard Class : Not Regulated

I.D. No. (UN/NA) : Not Regulated

DOT Label(s) : Not Regulated

Proper Shipping Name : Not Regulated

Hazard Class : Not Regulated

UN No. : Not Regulated

DOT/IMO Label : Not Regulated

Special Information : FLASH POINT: > 150 Deg C

Packing Group : Not Regulated

15.REGULATORY INFORMATION

SARA 311/312 Chronic health hazard: Not known

SARA 322/312 Acute health hazards: No

SARA311/312 Fire hazard: No

SARA311/312 Sudden Pressure: No

SARA311/312 Reactivity Hazard: No

CERCLA Hazardous substance: None

Section 313 toxic chemicals: None

TSCA inventory status: yes

16.OTHER INFORMATION

NFPA Hazard codes:

Health: 1 Fire: 1 Reactivity: 0

HMIS III rating

Health: 1 Flammability: 1 Physical Hazard: 0

Desscription:

PUREfos 168 is a hydrolytically stable phosphate processing stabilizer. As a secondary antioxidant PUREfos 168 reacts during processing with hydro-peroxides formed by auto-oxidation of polymers preventing process including degradation and extending the performance of primary antioxidant.

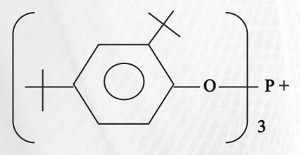

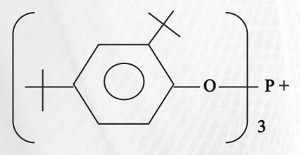

Chemical Name:

Tris (2, 4-ditert-butylphenyl) Phosphite.

CAS Number: 31570-04-4

Chemical structure:

Typical Properties

Product Form : Solid

Melting Range : 181 - 186oC

Molecular Weight : 646.9 g/mol

Solubility (percent by weight, 20°C)

Specification

Applications

PUREfos 168 is a hydrolytically stable phosphite processing stabilizer as a secondary antioxidant. It reacts during processing with hydroperoxides formed by autoxidation of polymers preventing process induced degradation. PUREfos 168 reacts with hydroperoxides to yield non-radical products, therefore called hydroperoxide decomposer. Purefos-168 is synergistically combined with other primary antioxidant such as Purestab-1010 and Purestab-1076 for applied used in polyolefins or olefin-copolymers such as HDPE, LLDPE, PP, EVA as well as PC, PA. The blends can also be used in engineering plastics such as PBT, PET, and styrenics, elastomers like PS, ABS, BR, SBS and tickifier resins, adhesives. Purefos-168 protects polymers which are prone to oxidation during processing steps (compounding, pelletizing, fabrication and recycling) from molecular weight change (e.g. chain scission of PP, cross linking of PE) and prevent discoloration.

Features and benefits

PUREfos 168 is an organophosphate of low volatility and is particularly resistant to hydrolysis. It protects polymers which are prone to oxidation, during the processing steps (Compounding/pelletizing, fabrication and recycling) from molecular weight change (e.g. chain scission/cross linking) and prevent discoloration. Purefos-168 performs best when combined with other Polygel antioxidants.

Guidelines for Use

Recommended loading concentrations range between .0.05% and 0.2 % combined with appropriate levels of other additives are used for the processing stabilization of polymers. The optimum level is application specific.

Storage

This product may be stored up to two years in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.

Safety

Please consult the Safety Data Sheet (SDS) prior to handling or using this product.

PUREfos 168 is a hydrolytically stable phosphate processing stabilizer. As a secondary antioxidant PUREfos 168 reacts during processing with hydro-peroxides formed by auto-oxidation of polymers preventing process including degradation and extending the performance of primary antioxidant.

Chemical Name:

Tris (2, 4-ditert-butylphenyl) Phosphite.

CAS Number: 31570-04-4

Chemical structure:

Typical Properties

Product Form : Solid

Melting Range : 181 - 186oC

Molecular Weight : 646.9 g/mol

Solubility (percent by weight, 20°C)

| % w/w | % w/w | ||

| Acetone | 01.0 | Chloroform | 36.0 |

| Cyclohexane Benzene | 16.0 | Ethanol | 0.01 |

| Ethyl acetate | 04.0 | n-Hexane | 11.0 |

| Methanol | <0.01 | Toluene | 30.0 |

| Methylene chloride | 36.0 | Water | < 0.01 |

Specification

| Parameters | Specification |

| Appearance | White free flowing powder |

| Volatile | 0.5 % Max |

| Color of solution | Clear solution |

| (10gms in 100 ml Toluene) | |

| Transmittance | @ 425 nm 97 % Min |

| (10 gms in 100 ml Toluene) | @ 500 nm 98 % Min |

| Hydrolytic test | 20 Hrs Min |

| Assay | 99 % Min |

Applications

PUREfos 168 is a hydrolytically stable phosphite processing stabilizer as a secondary antioxidant. It reacts during processing with hydroperoxides formed by autoxidation of polymers preventing process induced degradation. PUREfos 168 reacts with hydroperoxides to yield non-radical products, therefore called hydroperoxide decomposer. Purefos-168 is synergistically combined with other primary antioxidant such as Purestab-1010 and Purestab-1076 for applied used in polyolefins or olefin-copolymers such as HDPE, LLDPE, PP, EVA as well as PC, PA. The blends can also be used in engineering plastics such as PBT, PET, and styrenics, elastomers like PS, ABS, BR, SBS and tickifier resins, adhesives. Purefos-168 protects polymers which are prone to oxidation during processing steps (compounding, pelletizing, fabrication and recycling) from molecular weight change (e.g. chain scission of PP, cross linking of PE) and prevent discoloration.

Features and benefits

PUREfos 168 is an organophosphate of low volatility and is particularly resistant to hydrolysis. It protects polymers which are prone to oxidation, during the processing steps (Compounding/pelletizing, fabrication and recycling) from molecular weight change (e.g. chain scission/cross linking) and prevent discoloration. Purefos-168 performs best when combined with other Polygel antioxidants.

Guidelines for Use

Recommended loading concentrations range between .0.05% and 0.2 % combined with appropriate levels of other additives are used for the processing stabilization of polymers. The optimum level is application specific.

Storage

This product may be stored up to two years in a sealed container. Containers should be kept tightly closed when not in use and stored in a cool, dry place.

Safety

Please consult the Safety Data Sheet (SDS) prior to handling or using this product.

Enquire now